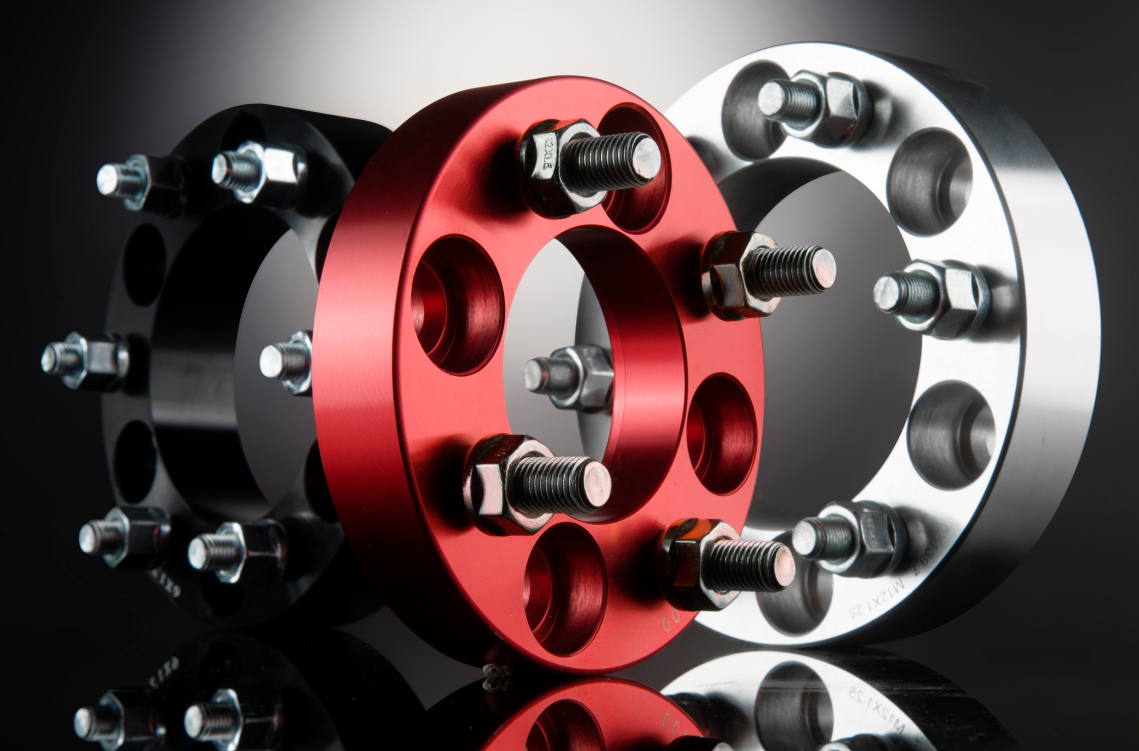

Yokelink providing high-quality wheel accessories, including Wheel boltss, Wheel nuts and Wheel spacers. Wheel spacers are essential components that are used to create additional space between the wheel hub assembly and the wheel. They are designed to improve vehicle stability, enhance handling, and allow for the installation of larger tires. Wheel Accessories,Wheel Lug Nuts,Truck Wheel Spacers,Chrome Wheel Nuts,Aluminum Alloy,Wheel Spacers Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com

Model selection method for internal return pump

Selecting the right internal return pump involves several crucial considerations to ensure both efficient operation and long-term durability. First, choose a submersible multi-stage pump that matches the maximum extraction capacity of the water source well. The pump's capacity should align closely with the actual inflow of water in the well, ideally being equal to or slightly lower than the well's exploitation volume. Pumping beyond this limit can lead to excessive water withdrawal, which not only shortens the lifespan of the deep well pump but may also damage the filtration system, potentially causing sand to infiltrate and leading to costly well failure.

Second, the diameter of the internal return pump must correspond to the well’s inner diameter. For smooth operation and minimal wear, there should be sufficient space around the pump—typically about 20-40mm larger than the pump's maximum diameter. This creates an optimal annular gap of 10-20mm between the pump and the well wall, which enhances groundwater collection efficiency and reduces operational friction. Ensuring this clearance is vital for extending the service life of both the well and the pump.

Third, the pump head should face downward toward the solid casing (not the perforated section) of the well. Misalignment here could result in continuous sand surges during operation, damaging the pump or even compromising the integrity of the well. Based on geological survey data and hydrological conditions, such as aquifer depth, thickness, and lithology, engineers should carefully plan the placement and configuration of the pump to avoid future complications.

Fourth, the selection of the deep well submersible pump should reflect the specific extraction needs of the water source well. Hydrogeological feasibility studies should guide decisions regarding pump specifications and models, ensuring they match the well’s inflow rate while optimizing overall well design.

Lastly, consider total head losses when selecting the pump. The pump’s diameter, stage count, and power must accommodate the pressure head from the pump to the surface storage tank. While higher heads offer greater potential, they demand more powerful motors, increasing wear risks like bearing seizure or blade erosion. Using a high-head pump for low-pressure applications can lead to inefficient, high-flow operations that stress the system, causing premature wear and increased costs. Instead, aim for a pump head that matches or slightly exceeds total head losses during operation to maintain balance and efficiency. Neglecting these principles can result in filter clogging, scaling issues, and unnecessary energy expenses, ultimately reducing the pump's operational lifespan and increasing maintenance demands.